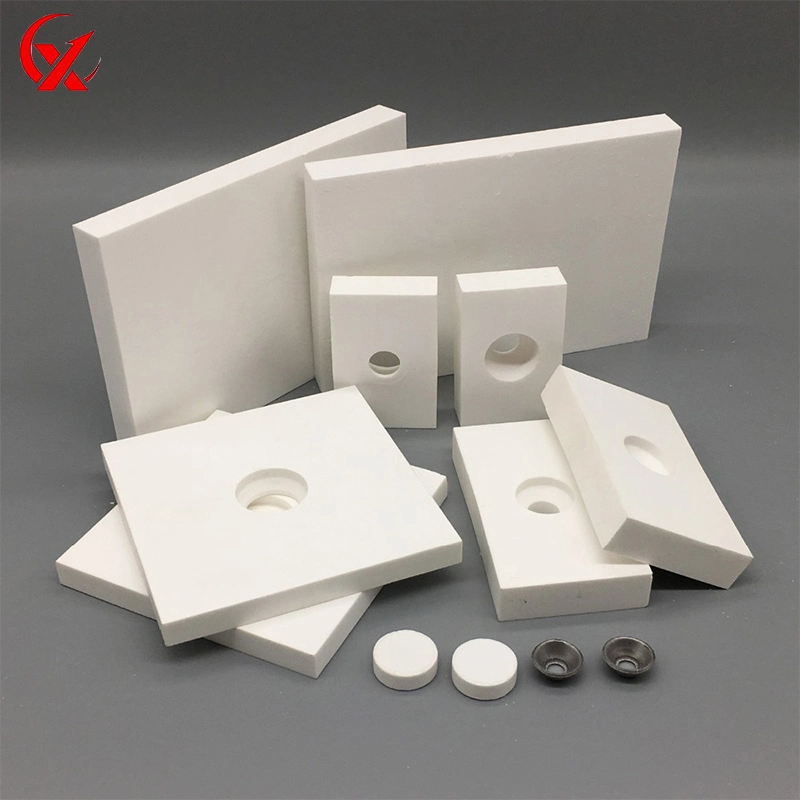

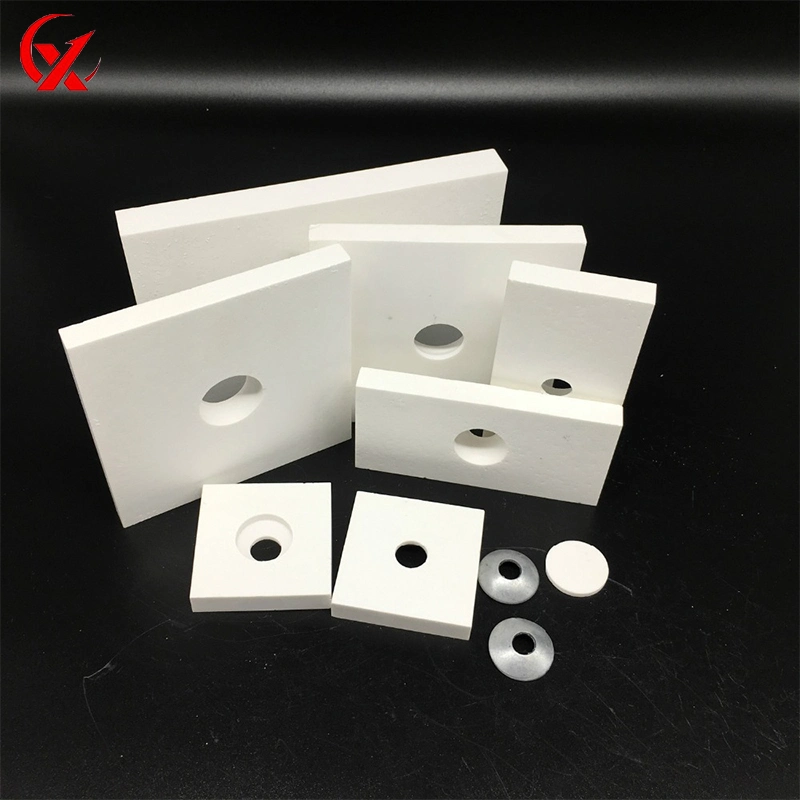

Alumina Wear Resistant Lining Tiles and Brick

Technical Parameters:

| Item | 85 Series | 92Series | 95 Series | 99Series |

| AL2O3(%) | ≥83.5 | ≥92 | ≥95 | ≥99 |

| Moh's hardness(Mohs) | 9 | 9 | 9 | 9 |

| Water absorption rate(%) | ≤0.02 | ≤0.02 | ≤0.02 | ≤0.02 |

| Breaking strength(n/mm) | 38 | 40 | 42 | 48 |

| Bending strength(Mpa) | 235 | 255 | 275 | 300 |

| Bulk density(g/cm3) | ≥3.30 | ≥3.60 | ≥3.68 | 3.83 |

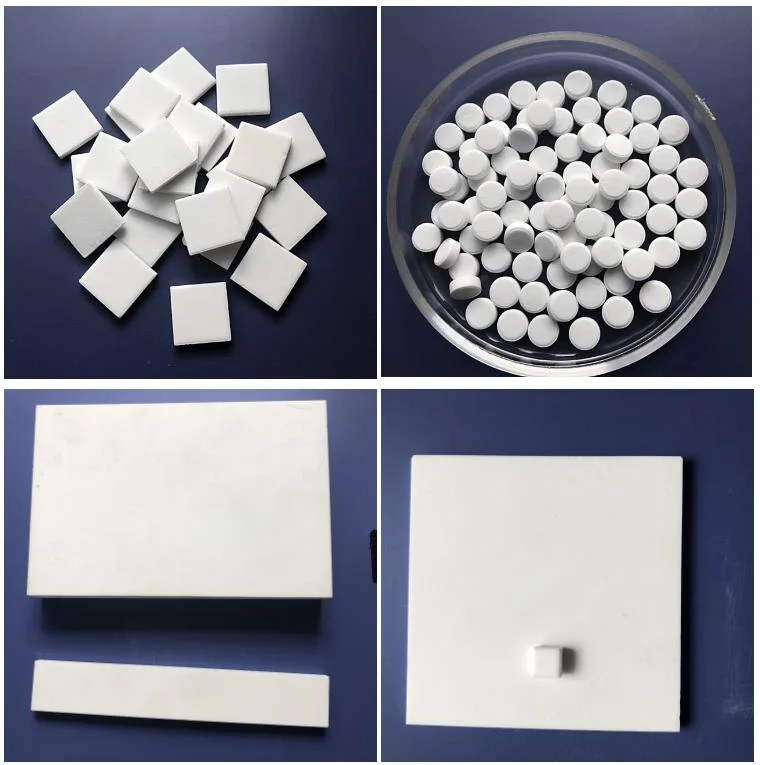

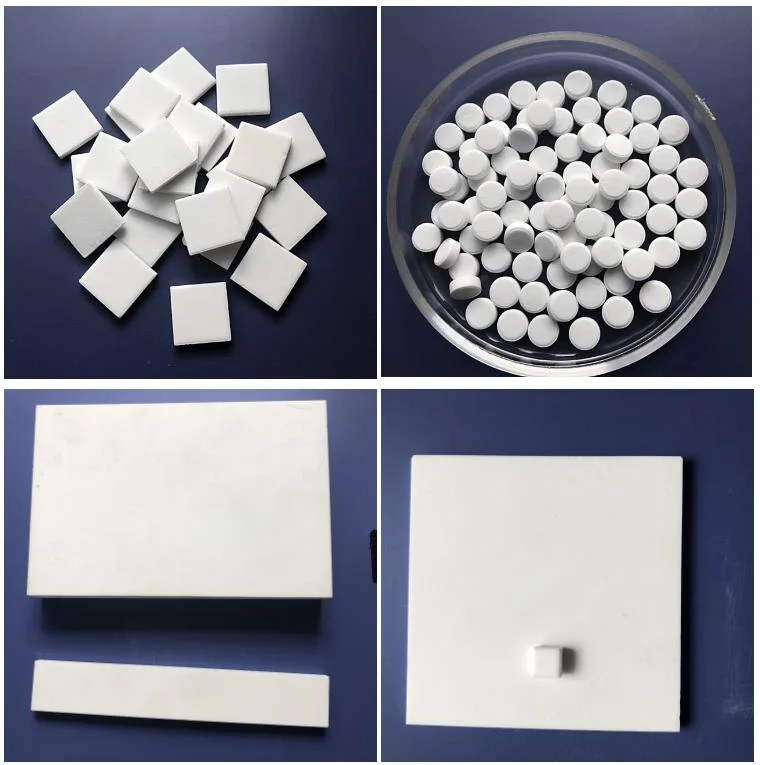

Partial product specifications:

| Item | Length /mm | Width/mm | Thickness/mm | Note |

| 10*10 mat | 10 | 10 | 3-10 | Square |

| 17.5*17.5 mat | 17.5 | 17.5 | 4-10 | Square |

| 20*20 mat | 20 | 20 | 3-20 | Square |

| 11.55 *11.55 mat | 11.55 | 11.55 | 3-10 | Square |

| 12.5*12.5 mat | 12.5 | 12.5 | 3-10 | Square |

| 50*50 | 50 | 50 | 5-15 | Flat tile |

| 100*100 | 100 | 100 | 6.5-15 | Flat tile |

| 120*80 | 120 | 80 | 6-20 | Welding tile with hole |

| 150*60 | 150 | 60 | 10-25 | Flat tile |

| 150*100 | 150 | 100 | 6-50 | Flat tile |

| 150*100 | 150 | 100 | 12-20 | Welding tile with hole |

| 100*81.6 / 78.5 | 100 | 81.6 / 78.5 | 20 | Curved tile |

Product features:

High temperature burning, wear resistance, impact resistance, acid and alkali resistance, construction convenience, etc.Its theoretical wear resistance is equivalent to 260 times that of manganese steel and 170 times that of chrome steel, which can effectively extend the service life of equipment.Vulnerable part.

Application:

Coal, petroleum, mining, steel, power plants and other industries, material handling equipment or wear-resistant materials that flow through the surface of the pipeline, the main role is to effectively resist the impact of materials on the pipeline wall.

Processing

Company Show:

Zibo Chaoxin Ceramics Technology Co., Ltd.As a new and hi-tech ceramic manufacturer with excellent abilities of technology research, manufacture and distribution, is located in Zibo National New and High-tech Industrial Development Zone in Shandong Province, China.

We mainly produce various kinds of fine ceramic products, which in material of zirconium oxide (ZrO2), alumina (Al2O3), zirconium silicate (ZrSiO4), mullite (A3S2) and composite oxide ceramics.Products include ceramic grinding ball(diameter 0.3mm~30mm), Ceramic Liner(mud pump spare part), Ceramic Plunger(oil pump spare part), Alumina Lining Bricks(ceramic ball mill machine), Wear-Resistant Sleeves, Wear-Resistant Lining Tiles/Mat, ball mill machine, Cyclone, and chemical ball, etc.

High temperature burning, wear resistance, impact resistance, acid and alkali resistance, construction convenience, etc.Its theoretical wear resistance is equivalent to 260 times that of manganese steel and 170 times that of chrome steel, which can effectively extend the service life of equipment.Vulnerable part.

Application:

Coal, petroleum, mining, steel, power plants and other industries, material handling equipment or wear-resistant materials that flow through the surface of the pipeline, the main role is to effectively resist the impact of materials on the pipeline wall.

Processing

Company Show:

Zibo Chaoxin Ceramics Technology Co., Ltd.As a new and hi-tech ceramic manufacturer with excellent abilities of technology research, manufacture and distribution, is located in Zibo National New and High-tech Industrial Development Zone in Shandong Province, China.

We mainly produce various kinds of fine ceramic products, which in material of zirconium oxide (ZrO2), alumina (Al2O3), zirconium silicate (ZrSiO4), mullite (A3S2) and composite oxide ceramics.Products include ceramic grinding ball(diameter 0.3mm~30mm), Ceramic Liner(mud pump spare part), Ceramic Plunger(oil pump spare part), Alumina Lining Bricks(ceramic ball mill machine), Wear-Resistant Sleeves, Wear-Resistant Lining Tiles/Mat, ball mill machine, Cyclone, and chemical ball, etc.

Certifications

Exhibition

Packaging and transportation

FAQ:

01.Product packaging

Depending on the situation, generally fumigation-free trays

02.Product production cycle?

A small number of products? How much

Different products should be different, can you give a rough range? Such as 3-14 days or 7-30 days

03.Production cycle of customized products?

A large number of products? How much

(Inferred from lead time)

04.product lead times 3-7 days, large 7-15 days, or? ?

Delivery is generally 5-15 days, except for stock and drawing customization

The spot generally uses the payment voucher as the delivery date, and the customization may be delivered within 15-35 days according to the actual situation.

Exhibition

Packaging and transportation

FAQ:

01.Product packaging

Depending on the situation, generally fumigation-free trays

02.Product production cycle?

A small number of products? How much

Different products should be different, can you give a rough range? Such as 3-14 days or 7-30 days

03.Production cycle of customized products?

A large number of products? How much

(Inferred from lead time)

04.product lead times 3-7 days, large 7-15 days, or? ?

Delivery is generally 5-15 days, except for stock and drawing customization

The spot generally uses the payment voucher as the delivery date, and the customization may be delivered within 15-35 days according to the actual situation.

Your inquiry is welcoming!~~

Sales Manager:Miss Ginkgo Bai